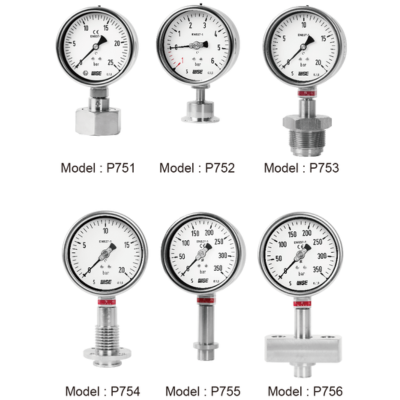

P750 Series_Sanitary pressure gauge

Categories: Diaphragm, General Pressure Gauge•Switch•Recorder, WISE

Service intended

P750 series have diaphragm seal to be combined with a pressure gauge. These series are suitable to be used for the situation where corrosive, contaminated, hot, and viscous pressure mediums are present, and it could be used for a chemical, food, beverage, biochemical, and pharmaceutical industry.

| Nominal diameter | 63, 80 and 100 mm |

| Accuracy | 63 and 80 mm : ±1.6 % of full scale 100 mm : ±1.0 % of full scale |

| Pressure range (MPa, kPa, bar) | Steady : 75 % of full scale (63 and 80 mm) 100 % of full scale (100 mm) Over range protection : 130 % of full scale |

| Working pressure | Steady : 75 % of full scale Over range protection : 130 % of full scale |

| Working temperature | Ambient : -20 ~ 65 °C Fluid : Max. 121 °C |

| Temperature effect | Accuracy at temperature above and below the reference temperature (20 ℃) will be effected by approximately ±0.5 % per 10 ℃ of full scale |

Standard features

| Process connection | 316SS P751 : 1½” and 2″ Nut P752 : 1″, 1½”, 2″, clamp connection P753 : PF¾”, PF1″, PF1½”, male screw P754 : Standard and non standard flange P755 : Homogenizer P756 : Homogenizer flange (95 x 43 x 28 mm) |

| Body | Stainless steel (316SS) |

| Diaphragm | Stainless steel (316L SS) Electropolished diaphragm Surface roughness : ≤ Ra : 0.8 ㎛ |

| System filling | Food grade oil (FDA certified) |

| Certificates | ATEX II 2G Ex h IIC T6…T1 Gb ATEX II 2D Ex h IIIC T85°C….T450°C Db |

© WISE Control Inc. All rights reserved. ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.