Overview

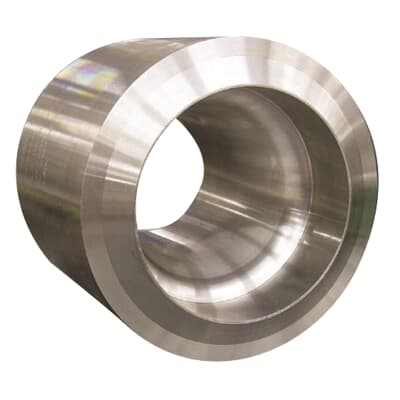

Flow nozzles do not rely on a sharp edge (which can degrade over time) to maintain accuracy and therefore offer excellent long-term accuracy with less wear and reduced possibility of distortion. They are often used for flow testing on steam-raising plant.

A flow nozzle can measure higher flow rates than an equivalent orifice plate at the same design differential pressure. The flow nozzle is available to 3 standards and in designs for either clamping between flanges (within the bolt circle) or for welding into the pipe.

Data

Flow nozzles are available in three basic designs:

- ISA 1932 nozzle

- Long radius nozzle

- ASME throat tap nozzle

Each design is slightly different and is covered by ISO5167:2003, with the exception of the ASME throat tap nozzle. The ASME nozzle can also be supplied in a pipe section to meet the requirements of ASME Performance Test Code 6 (PTC-6) for steam turbine testing.