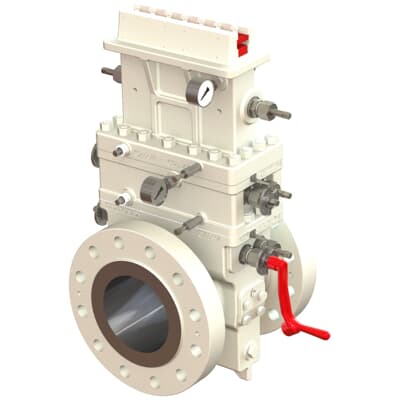

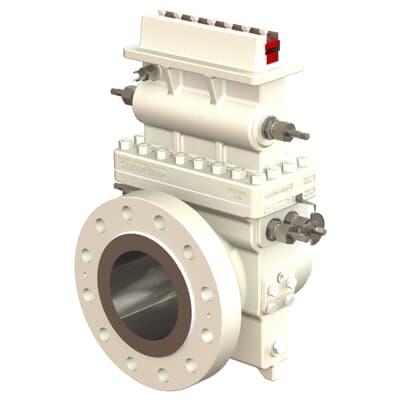

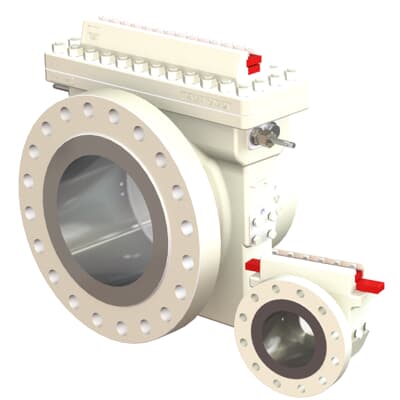

Overview

A dual-chamber orifice fitting with double block and bleed (DBB) isolation, suitable for fiscal (custody transfer) applications in locations where

– proven isolation is required and

– pipeline will not/cannot be shut down (or bypassed and isolated) or depressurised for service

FPD220 offers dual isolation, with two independent chamber seals, ensuring maximum safety during live orifice plate changes or during routine inspection. This is visually confirmed by two pressure gauges integrated into the unit.

Data

- Proven Dual isolation (DBB) of the process from the environment during orifice plate changes

– no need to isolate the complete metering stream - Minimized venting of gas volume

– only the small volume contained within the meter upper chamber is vented - Substantial saving in operating costs and production

– potential annual savings of $50k per stream in reduced downtime

– typically only 30 minutes to exchange a plate instead of many hours - Elimination of parallel streams or bypass lines

– less maintenance and less inspection time

– reduced weight and cost

– a higher level of visible safety